The concept of torsion plays a crucial role in studying mechanics and material science. One of the most common scenarios where torsion is applied is when a cylinder is subjected to a twisting force. Torsion of a cylinder derivation is a key part of engineering, particularly when analysing how materials respond to torsional stress. In this article, we will explore the concept of torsion and how it affects a cylinder and walk through the derivation process for a better understanding. The torsion of a cylinder has practical applications in everything from automotive engineering to mechanical design, making its study essential for engineers and scientists alike.

What is Torsion

Before delving into the torsion of a cylinder derivation, it’s essential to define torsion itself. Torsion refers to an object’s twisting or rotational deformation when a torque (rotational force) is applied to its longitudinal axis. This torque causes the material to deform so that one end of the object rotates relative to the other. Torsion happens when you twist a cylindrical object, such as a rod or shaft, at one end while the other remains fixed.

Torsion can cause both shear stress and shear strain in a cylindrical structure. The distribution of these stresses across the cylinder’s cross-section depends on factors such as the material properties, the geometry of the cylinder, and the magnitude of the applied torque.

Importance of Torsion in Engineering

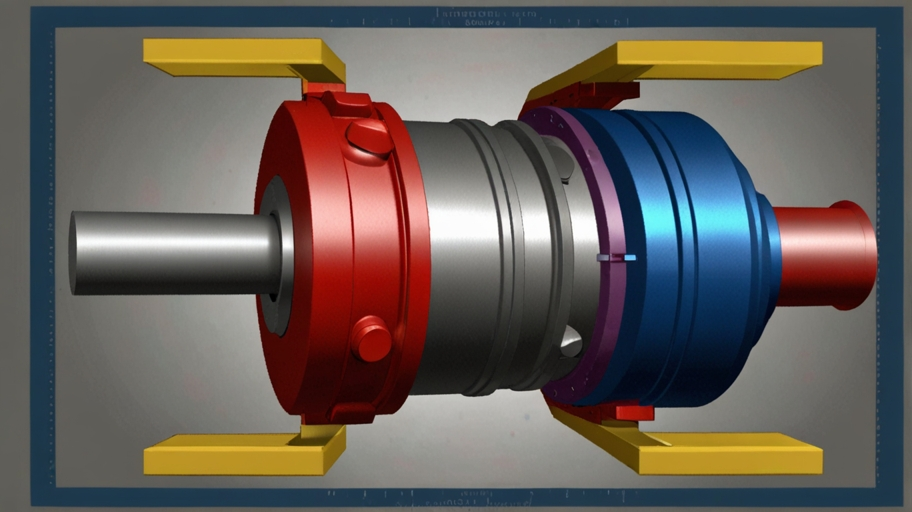

The torsion of a cylinder derivation is practical in various engineering applications. Engineers must understand how torsion affects the material when designing shafts, gears, or rotating components. This understanding is crucial for creating components that can withstand torsional forces without failure.

For instance, automotive shafts, aeroplane wings, and structural beams often experience torsion. The torsion of a cylinder derivation helps engineers determine how much the material will twist and whether it will maintain its integrity under applied torque. Failure to account for torsional stress can lead to catastrophic failures in mechanical systems, making the study of torsion essential in the design process.

Derivation of the Torsion of a Cylinder

To derive the torsion of a cylinder derivation, we need to start with the basic principles of materials mechanics. Consider a solid cylinder or shaft of radius R, length L, and subjected to a torque TTT at one of its ends, with the other end being fixed. The cylinder is assumed to be under pure torsion, meaning no bending or axial load is acting on it.

1. Shear Stress Due to Torsion

When torque is applied to the cylinder, shear stress develops along the surface of the cylinder. The shear stress is most significant at the outer surface and decreases as we move toward the centre of the cylinder. The shear stress τ\tauτ at a distance or from the centre of the cylinder’s cross-section is given by the following equation:

τ=TrJ\tau = \frac{T r}{J}τ=JTr

Where:

- TTT is the applied torque,

- R is the radial distance from the centre of the cylinder, R is the spiral separation from the focal point of the chamber,

- JJJ is the polar moment of inertia of the cylinder’s cross-section.

For a solid cylinder, the polar moment of inertia the equation gives JJJ:

J=πR42J = \frac{\pi R^4}{2}J=2πR4

2. Angle of Twist

Next, we calculate the twist angle, representing how much the cylinder rotates under the applied torque. The angle of twist θ\thetaθ is related to the applied torque, the material’s shear modulus GGG, and the length of the cylinder L. The equation for the angle of twist is:

θ=TLJG\theta = \frac{T L}{J G}θ=JGTL

Where:

- TTT is the applied torque,

- It is the length of the cylinder,

- JJJ is the polar moment of inertia,

- GGG is the shear modulus of the material.

3. Shear Strain and Shear Stress Distribution

The shear strain at any point along the cylinder’s surface due to torsion is given by:

γ=rθL\gamma = \frac{r \theta}{L}γ=Lrθ

Where:

- γ\gammaγ is the shear strain,

- is the radial distance from the centre of the cylinder,

- θ\thetaθ is the angle of twist,

- It is the length of the cylinder.

This relationship between shear strain and radial distance helps us understand how the material deforms under torsion. The torsion of a cylinder derivation shows that the outermost fibres of the cylinder experience the most excellent shear strain, while the fibres near the centre experience minimal strain.

Application of Torsion of a Cylinder Derivation

The torsion of a cylinder derivation is widely used in practical applications. The equations above allow engineers to calculate the twist and shear stress a cylinder will experience under applied torque. This is fundamental for guaranteeing the well-being and dependability of mechanical frameworks.

For example, in the design of rotating shafts, the torsion of a cylinder derivation allows engineers to choose materials that can withstand the applied torque without failing. Additionally, it helps determine the required diameter of the shaft to ensure that the shear stress is within safe limits.

In the case of a car’s drive shaft, for instance, understanding torsion helps designs that can transfer power from the engine to the wheels without excessive deformation. Similarly, in the aerospace industry, the torsion of wings and other structural components is carefully considered to ensure the aircraft remains stable under various loading conditions.

Factors Affecting Torsion

Several factors affect the torsion experienced by a cylinder. The torsion of a cylinder derivation is based on the assumption that the material is homogeneous and isotropic, but in real-world applications, materials may have variations that can affect the results.

Some of the factors that influence torsion in cylindrical objects include:

- Material properties: The shear modulus GGG varies with different materials. A material with a higher shear modulus will resist torsion more effectively than one with a lower one.

- Geometry: The radius and length of the cylinder play a significant role in determining the amount of twist. A larger radius or longer length will lead to more considerable deformation under the same applied torque.

- Boundary conditions: How the cylinder is fixed or supported can affect the torsional behaviour. For example, if both ends of the cylinder are fixed, the torque distribution and the resulting twist will differ from a scenario where one end is free to rotate.

Practical Examples of Torsion in Cylindrical Structures

The torsion of a cylinder derivation is not just an academic exercise; it has real-world applications in various industries. Some practical examples include:

- Drive shafts in vehicles: The drive shaft in a car or truck is subjected to torsion as it transmits power from the engine to the wheels. Engineers use the torsion of a cylinder derivation to ensure that the drive shaft is strong enough to withstand the twisting forces during operation.

- Helicopter rotors: The rotor blades of a helicopter are long, cylindrical structures that experience torsion as they rotate. Understanding the torsion of the cylinder derivation helps engineers design rotor blades that can withstand these forces without failure.

- Industrial machinery: Shafts, beams, and other cylindrical components in machinery experience torsion when transmitting power or supporting loads. Accurate torsion calculations are crucial for ensuring the longevity and safety of industrial machinery.

Conclusion

The torsion of a cylinder derivation is a fundamental concept in mechanics and material science. By understanding how torque affects the deformation of a cylinder, engineers can design safe, efficient, and durable components. Calculating the shear stress, angle of twist, and shear strain in the torsion of a cylinder derivation structure is essential for ensuring the integrity of mechanical systems subjected to torsional forces. From automotive engineering to aerospace design, the principles derived from the torsion of a cylinder are applied across a wide range of industries, making it a crucial area of study for anyone involved in the engineering field.